The Rise of Die Casting in China: Manufacturing Excellence and Global Impact

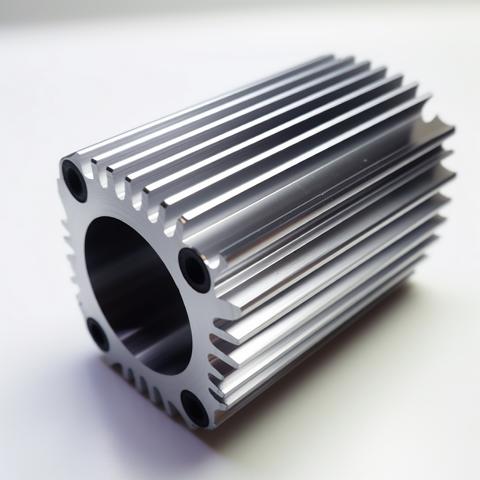

Die casting China has become a major force in the global manufacturing industry, supplying high-quality metal components to industries such as automotive, aerospace, electronics, and consumer goods. With advanced production techniques, cost-effective manufacturing, and strong supply chain networks, China has established itself as a leader in aluminum die casting. Companies seeking lightweight, durable, and precision-engineered […]

The Rise of Die Casting in China: Manufacturing Excellence and Global Impact Read More »