What is Acrylic Plastic?

Acrylic plastic, often referred to by its chemical name Polymethyl Methacrylate (PMMA), is a transparent thermoplastic material known for its lightweight nature, durability, and optical clarity. Widely recognized as a versatile alternative to glass, acrylic is used across various industries, including construction, automotive, healthcare, and consumer goods. Its unique combination of physical and chemical properties makes it a popular choice for both functional and aesthetic applications.

Acrylic plastic is a synthetic polymer derived from methyl methacrylate (MMA), a type of monomer. During the manufacturing process, MMA molecules undergo polymerization to form PMMA, resulting in a strong and stable material. This process produces a material that is lightweight, shatter-resistant, and highly transparent, allowing up to 92% of visible light to pass through. Its clarity rivals that of glass, making it a preferred choice for applications requiring a clear, polished surface.

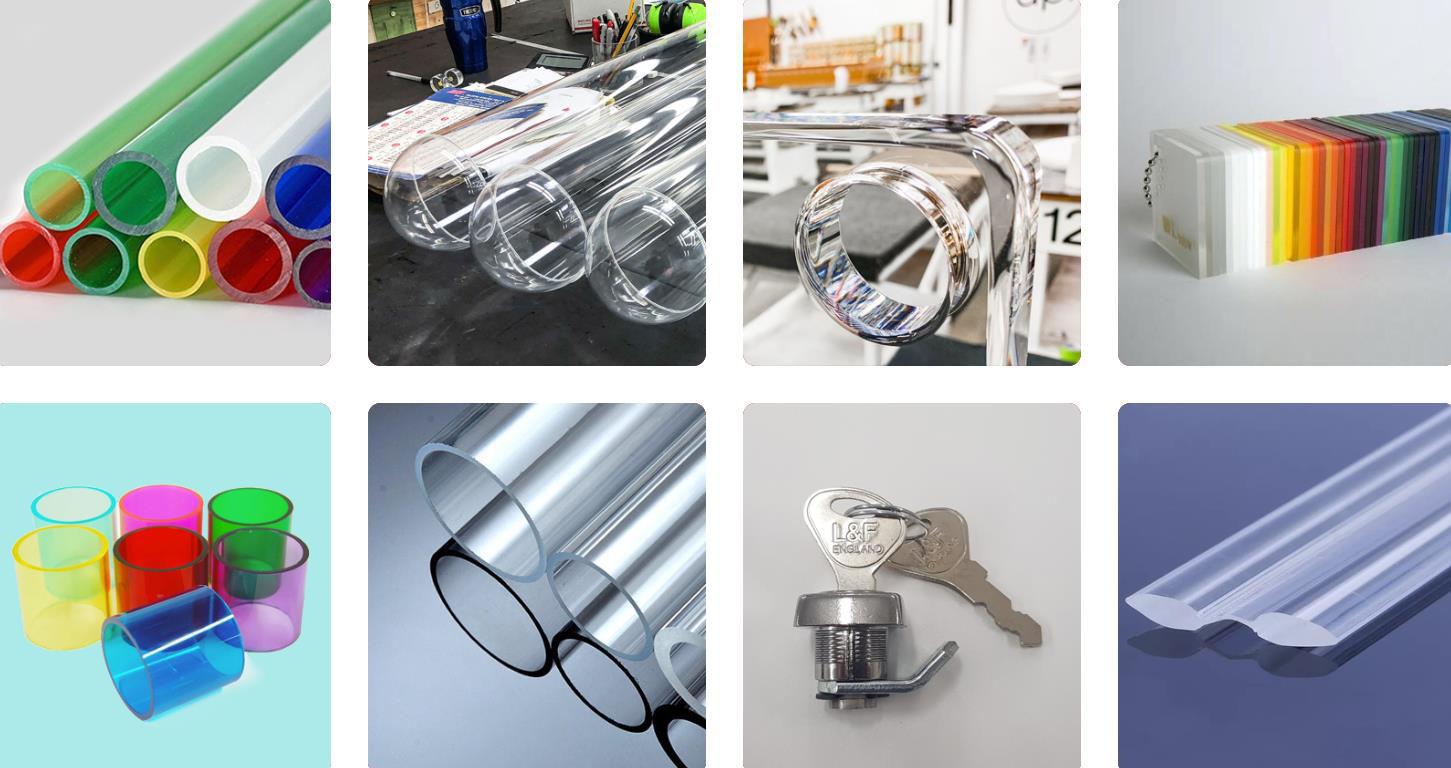

One of the defining characteristics of acrylic plastic is its thermoplastic nature. This means it softens when heated and can be molded into various shapes, which then harden upon cooling. This property allows manufacturers to create intricate designs and custom shapes, making it an incredibly adaptable material. Additionally, PMMA is available in various forms, including sheets, rods, and tubes, offering flexibility for diverse applications.

Understanding PMMA Plastic (Polymethyl Methacrylate)

PMMA plastic, or Polymethyl Methacrylate, is the technical name for acrylic plastic. It is sometimes marketed under popular brand names like Plexiglas, Lucite, and Acrylite. PMMA is valued for its exceptional optical properties, which make it an ideal material for products like display cases, signage, and lenses.

Unlike other plastics, PMMA does not contain harmful chemicals like Bisphenol A (BPA), making it a safer and more environmentally friendly option. Its non-toxic composition and ability to resist UV radiation contribute to its widespread use in outdoor applications. PMMA’s chemical stability also ensures that it remains durable over time, even when exposed to environmental factors such as sunlight, moisture, and temperature variations.

Another significant advantage of PMMA is its ability to be easily colored or coated. This versatility allows manufacturers to create vibrant, custom-colored designs while maintaining the material’s inherent clarity and strength. Whether in its clear or tinted form, PMMA plastic delivers a polished, high-quality finish.

Key Characteristics That Set Acrylic Plastic Apart

Several characteristics distinguish acrylic plastic from other materials, such as glass and polycarbonate. First and foremost, acrylic is significantly lighter than glass, weighing about half as much while offering comparable transparency. This makes it easier to handle, transport, and install in applications where weight is a concern, such as skylights or vehicle windows.

Acrylic plastic is also highly resistant to impact, making it less likely to shatter or crack compared to glass. While it is not as impact-resistant as polycarbonate, it offers superior scratch resistance and can be treated with additional coatings to enhance its durability.

Another key feature is its weather and UV resistance. Acrylic plastic maintains its clarity and structural integrity even after prolonged exposure to sunlight, making it a preferred choice for outdoor signage, greenhouse panels, and protective barriers. Additionally, its ease of fabrication and compatibility with adhesives and solvents simplify the manufacturing process, allowing for a wide range of applications.

Acrylic plastic is a versatile material with remarkable optical clarity, durability, and adaptability. Its chemical composition, thermoplastic properties, and unique characteristics make it a standout choice for industries seeking a lightweight, cost-effective, and environmentally conscious alternative to traditional materials like glass.

Is Acrylic Plastic Anti-Scratch?

Acrylic plastic, or Polymethyl Methacrylate (PMMA), is a popular material known for its clarity, lightweight nature, and durability. However, when it comes to scratch resistance, acrylic has certain limitations compared to other materials. While it offers some level of surface durability, it is not inherently anti-scratch. This characteristic can be improved through coatings and treatments, making acrylic suitable for a wide range of applications where resistance to wear and tear is essential. Below, we explore the scratch resistance of acrylic, compare it with other plastics like polycarbonate, and examine how coatings enhance its performance.

Surface Durability and Scratch Resistance of Acrylic

Acrylic plastic is a durable material that can withstand significant impacts without shattering, making it an excellent alternative to glass. However, its surface is relatively soft, which makes it susceptible to scratches from sharp objects or abrasive materials. Everyday handling, cleaning with rough fabrics, or exposure to grit can result in minor surface damage.

Despite these vulnerabilities, acrylic remains a popular choice for many applications because scratches on its surface can often be polished out using specific techniques. For example, fine scratches can be buffed away with polishing compounds, restoring the material’s clarity and smoothness. While this mitigates some concerns about scratch resistance, it does not eliminate the need for additional protection in high-wear environments.

Comparing Acrylic with Other Plastics Like Polycarbonate

When evaluating the scratch resistance of acrylic against other plastics like polycarbonate, acrylic tends to fall behind. Polycarbonate, another popular thermoplastic, is naturally more resistant to scratches and impact, making it a preferred choice for applications requiring enhanced surface durability, such as safety glasses, protective shields, and automotive parts.

However, while polycarbonate is tougher, it has its own drawbacks. It is more prone to discoloration over time and is less UV resistant compared to acrylic. Acrylic, on the other hand, retains its optical clarity and resists yellowing even after prolonged exposure to sunlight, making it a better choice for outdoor applications like signage, greenhouse panels, and display cases.

For projects where both scratch resistance and clarity are essential, acrylic can be treated with specialized coatings to enhance its durability. While polycarbonate may provide better natural scratch resistance, the superior clarity and weather resistance of acrylic make it a strong competitor in many applications.

How Coatings and Treatments Enhance Its Anti-Scratch Properties

One of the most effective ways to improve the scratch resistance of acrylic plastic is through the application of anti-scratch coatings. These coatings create a hard, protective layer on the surface of the material, significantly reducing its susceptibility to scratches. Common coatings include silicone-based or UV-cured options, which not only enhance scratch resistance but also improve chemical resistance and reduce glare.

Another treatment option is hardening through chemical or thermal processes. These treatments strengthen the surface, making it less prone to abrasion during everyday use. Manufacturers often offer pre-coated acrylic sheets or panels for industries that demand superior durability, such as automotive, aerospace, and consumer electronics.

Furthermore, proper maintenance practices can also extend the life of acrylic products. Using soft, non-abrasive cleaning materials and avoiding harsh chemicals help preserve the material’s surface integrity over time.

Advantages of Acrylic Plastic

Acrylic plastic, also known as Polymethyl Methacrylate (PMMA), is a versatile material that has found widespread use across various industries due to its remarkable properties. From its lightweight yet durable nature to its exceptional optical clarity and resistance to environmental factors, acrylic plastic offers numerous advantages that make it a preferred choice over traditional materials like glass and polycarbonate. Below, we explore the key benefits of acrylic plastic in detail.

Lightweight Yet Durable Material for Versatile Applications

One of the standout advantages of acrylic plastic is its lightweight nature. It weighs approximately half as much as glass, making it easier to handle, transport, and install. Despite being lightweight, acrylic is highly durable and impact-resistant, offering significant strength compared to glass, which is prone to shattering. This combination of lightness and durability makes acrylic ideal for applications ranging from home decor and signage to industrial components and automotive parts.

For instance, in the automotive industry, acrylic is often used in light fixtures and windshields due to its ability to withstand impacts and reduce overall vehicle weight. Similarly, in retail and exhibitions, its lightweight properties make it easy to create and move custom displays without compromising structural integrity. Its versatility ensures that it can be adapted for both functional and aesthetic purposes in countless industries.

Optical Clarity and Aesthetic Appeal in Various Designs

Acrylic plastic is renowned for its exceptional optical clarity, with the ability to transmit up to 92% of visible light. This clarity rivals, and in some cases surpasses, that of glass, making acrylic an excellent choice for applications where visual appeal is paramount. Products like display cases, aquariums, protective barriers, and decorative panels benefit from acrylic’s ability to provide a clear, distortion-free view.

Beyond clarity, acrylic’s aesthetic flexibility allows it to be shaped, tinted, or frosted to meet specific design requirements. It can be manufactured in various colors and finishes, offering endless possibilities for customization. This makes acrylic a preferred material for creative projects where both functionality and design play a crucial role, such as architectural features, furniture, and artistic installations.

Moreover, acrylic is resistant to discoloration over time, maintaining its transparency and polished appearance even after years of use. This durability ensures that products made from acrylic retain their aesthetic appeal, making it a cost-effective investment for both personal and professional use.

Weather Resistance and UV Stability for Outdoor Uses

Another significant advantage of acrylic plastic is its resistance to weather and UV radiation. Unlike glass or some other plastics, acrylic does not yellow, become brittle, or degrade when exposed to sunlight for extended periods. This makes it an ideal material for outdoor applications such as signage, greenhouse panels, skylights, and outdoor furniture.

Acrylic’s ability to withstand harsh weather conditions, including rain, wind, and temperature fluctuations, ensures its longevity in outdoor settings. Additionally, it resists moisture absorption, which prevents warping or swelling, further enhancing its performance in challenging environments.

In outdoor applications, acrylic can also be treated with anti-scratch or anti-glare coatings to improve its durability and functionality. These treatments enhance the material’s ability to perform in rugged conditions while maintaining its clear and attractive appearance.

Applications of PMMA Plastic

Polymethyl Methacrylate (PMMA), commonly known as acrylic plastic, is a versatile material with applications spanning numerous industries. Its unique properties, including exceptional clarity, durability, and weather resistance, make it a preferred choice for various uses, from functional components to aesthetic enhancements. Below, we delve into the key applications of PMMA plastic across industries, highlight its popular uses, and explore why it is favored in environmentally conscious projects.

Industries That Benefit from PMMA’s Properties: Automotive, Construction, and Healthcare

PMMA plastic plays a pivotal role in the automotive industry, where its lightweight and impact-resistant properties help improve vehicle efficiency and safety. It is often used in the production of car windows, light covers, and interior panels. For example, PMMA is a preferred material for headlight and taillight covers due to its ability to maintain optical clarity and resist weathering over time. Its lightweight nature contributes to reduced fuel consumption, aligning with the automotive sector’s focus on sustainability and efficiency.

In the construction industry, PMMA is widely utilized for architectural applications such as skylights, decorative panels, and noise barriers. Its high transparency and UV resistance make it ideal for glazing applications, where it offers a durable and visually appealing alternative to glass. Additionally, PMMA’s weather-resistant properties ensure longevity in outdoor installations, making it a reliable choice for construction projects.

The healthcare sector also relies on PMMA for a variety of applications. Its biocompatibility and non-toxic nature make it suitable for medical devices such as syringes, dental prosthetics, and optical lenses. PMMA’s ability to be sterilized without degrading further enhances its usability in medical environments. Its optical clarity is particularly valuable in surgical instruments and diagnostic equipment, where precision and visibility are critical.

Popular Uses of PMMA Plastic: Display Cases, Signage, and Medical Devices

PMMA plastic is a staple in the production of display cases for retail, museums, and exhibitions. Its excellent light transmission and shatter-resistant properties ensure that items are presented clearly and protected from damage. Whether used to showcase high-end jewelry or historical artifacts, PMMA offers a secure and aesthetically pleasing solution.

In signage, PMMA is prized for its ability to withstand outdoor conditions while maintaining vibrant colors and clear visibility. Its lightweight and easy-to-fabricate nature allow for the creation of custom shapes and designs, making it a go-to material for businesses looking to create eye-catching advertisements or directional signs.

The production of medical devices represents another important application. PMMA’s optical clarity and strength make it ideal for components like intraocular lenses, surgical instruments, and diagnostic equipment. Its compatibility with medical standards and ability to be molded into precise shapes ensure its continued use in advancing healthcare technology.

Why PMMA Plastic Is Preferred in Environmentally Conscious Projects

PMMA’s recyclability and long lifespan contribute to its growing popularity in environmentally conscious projects. Unlike many plastics, PMMA can be recycled and repurposed without significant degradation in quality, reducing waste and conserving resources. Its durability minimizes the need for frequent replacements, further lowering its environmental footprint.

Moreover, PMMA is often used as a substitute for less sustainable materials like traditional glass or certain non-recyclable plastics. For example, in solar panel construction, PMMA is preferred for its lightweight nature and UV resistance, helping improve energy efficiency in renewable energy systems.

Additionally, the production of PMMA has become increasingly energy-efficient, with advancements in manufacturing processes reducing emissions and resource consumption. These eco-friendly practices align with the growing demand for sustainable materials across industries.

Conclusion

Acrylic plastic, scientifically known as Polymethyl Methacrylate (PMMA), has proven itself as an indispensable material in modern applications due to its unique combination of properties. Its lightweight nature, exceptional optical clarity, and impressive durability make it a versatile choice across a wide range of industries, from automotive and construction to healthcare and retail. Acrylic’s ability to mimic the transparency of glass while offering superior impact resistance and weather stability has made it an ideal alternative for many functional and aesthetic purposes.

The advantages of acrylic extend beyond its practical benefits. Its flexibility in design, availability in various colors and finishes, and adaptability to customization allow it to meet the unique needs of businesses and individuals. Whether used in signage, display cases, medical devices, or environmentally conscious projects, acrylic stands out as a material that aligns with both innovation and sustainability.

Additionally, advancements in coatings, plastic mold techniques, and recycling practices have further enhanced its usability and eco-friendliness, ensuring its relevance in a world that values durability and environmental responsibility. Acrylic plastic’s enduring appeal lies in its ability to blend style, functionality, and sustainability seamlessly. As industries evolve and demand for efficient materials grows, acrylic continues to be a cornerstone of modern design and engineering solutions.